An order management system (OMS) not only supports all the stages in your company’s sales process, from order creation through customer delivery, it makes quick work of the logistics challenges inherent in an omnichannel world.

A key benefit of an OMS is that it provides a single, centralised system for managing orders from all sales channels: store, web, call centre, mobile and kiosk. Today’s customers demand a unified and simplified buying experience across all those channels, for example, when buying online and picking up in store (BOPIS).

An OMS helps you meet those demands more easily and efficiently.

Companies that sell directly to end consumers are the biggest purchasers of OMS software. However, companies of all sizes, in any industry with a supply chain—including health care, transportation, food service, automotive and pharmaceuticals—can also benefit from an OMS.

Analyst firm IHL Group estimates that the OMS market will grow from $710 billion globally to $1.16 billion by 2023 and says that an OMS is “the core system that allows for unified commerce to be successful.”

Retail “winners,” described by IHL as having greater than 10% growth, are 208% more likely to have an OMS in place than laggards.

Video: What Is Order Management?

Order Management Process

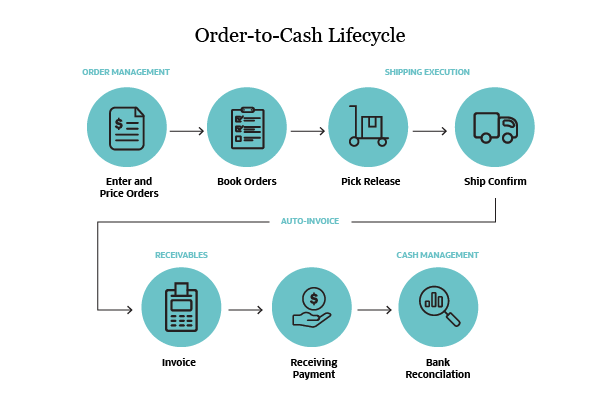

The order management process includes all the activities involved in taking, processing or receiving and fulfilling a customer order received via any sales channel. The process starts with creating new orders and establishing or updating customer accounts. Later steps include inventory-related activities such as checking and maintaining availability, picking, packing and finally shipping—and if you’re dealing with POS (point of sale systems), the process also extends to receiving payment. You may also hear the term “Order to Cash” used to refer to an extended view of the order management process that includes managing customer payments, returns and refunds.

Order Management Challenges

Traditionally, the order management process involved error-prone, manual tasks, especially in order entry and inventory management. Multiple hand-offs among departments increases overhead and the potential for error or fraud.

Then there’s inefficiency. When each department uses a different software system, that makes it difficult to get a clear view through the entire process. Disconnects between business groups result in redundancy, increased costs and customer frustration—for example, a customer placing an e-commerce order that cannot be fulfilled in a timely manner.

Let’s look at some challenges along the chain.

Order sourcing, allocation and fulfilment: How do you decide on the smartest fulfilment location based on your inventory and business rules? Merchants need to balance costs against delivery speed, decide when to release orders and notify each fulfilment location of which orders to fulfill.

Exceptions: An exception refers to any delay in delivery. Maybe the item is in high demand and went out of stock, or the order was lost. It’s important that the customer is kept informed and that item is either reshipped promptly or the order canceled.

Delivery: Customers may want to buy online and pick up in store, or the company may even be using its stores as warehouses to meet demand, increase inventory turns and reduce markdowns. That complicates logistics.

What Is an Order Management System (OMS)?

An OMS automates the entire order management process for your business, handling all the functions involved in fulfilling a customer order. It enables your employees and customers to view and track each order from start to finish, and it helps you analyse the overall efficiency of the process.

Perhaps most critically in a competitive environment, an OMS delivers fulfilment reporting and insights so retailers and distributors can track their critical KPIs. Was the order fulfilled quickly and for the lowest possible cost? If not, how can you improve? Are you seeing a spike in returns of certain items? If so, why, and how can you best handle that?

When a company has end-to-end order management insights, from allocation to orchestration and fulfilment, and extended through to payments and returns, it’s possible to drive out costs and increase efficiency.

Why Is an Order Management System Important?

An OMS can increase the efficiency of your order management process, automating many steps that previously required manual involvement. Because that improves the company’s ability to process orders efficiently and quickly, an OMS may increase customer satisfaction and enhance your cash flow and profitability.

Because ecommerce represents a greater percentage of sales—20.8% in Q2 2020, according to U.S. Department of Commerce data, the highest level on record—an OMS becomes increasingly important, for two primary reasons. First, it helps you meet customers’ expectations that they should be able to use any channel to order products, and should have a choice of whether to have them delivered or pick them up in stores, and should be able to return or exchange products anywhere.

Second, an OMS supports distributed order management: It helps you fulfill an order that involves shipping items from multiple locations, without a commensurate rise in costs.

An OMS also enables you to handle increases in sales volume as your business grows.

OMS Features

An OMS typically supports five main areas within the order management process.

- Sales channels. The OMS receives and consolidates information from all points of sale, including online, in-store and call centre. Some products also support orders from different global regions and multiple currencies.

- Sales support. Product information and availability are updated in real time for both your customers and your employees, including the customer service team. The OMS also supports omnichannel customer returns and exchanges.

- Customer database. This includes customer contact information and activity, including previous orders. That enables a service rep to recognise highly profitable customers and act accordingly.

- Inventory management. In addition to providing a consolidated view of inventory, which aids in managing and tracking stock levels, the OMS includes inventory management algorithms that route orders to the appropriate warehouses and identify the best shipping options. An OMS provides data that is used throughout the inventory management and fulfilment stages, including picking, packing, shipping and tracking.

- Accounting integration. Data from the OMS flows into your accounting system’s general ledger and subsidiary journals, such as accounts receivable and accounts payable, eliminating the need to reenter information or transfer it in a separate process.

OMS Benefits

The decision to implement an OMS often leads companies to examine their supply chains for bottlenecks and areas that can be improved. Sometimes, this analysis alone leads to improvements, such as faster fulfilment times. In addition, the OMS can deliver benefits such as:

- Tighter inventory management. Better visibility into sales helps you optimise inventory levels so that you meet customer demand while minimising excess stock. A consolidated view keeps you from missing a sale because inventory is in, for example, multiple locations. All of this can increase cash flow as well as improve customer loyalty and satisfaction.

- Reduced data entry. Because the same information is used across all areas of the sales and fulfilment process, less data entry is required, and that means less potential for errors.

- Visibility. Everyone in your organisation can access and track order status, enhancing customer service, and you can enable customers to track order status, too.

- Analysis. OMS dashboards can inform decision-making by highlighting sales patterns, tracking KPIs and forecasting sales.

How Does an Order Management System (OMS) Work?

An OMS begins with providing visibility into available-to-promise (ATP) inventory across your supply chain, both at your own warehouses and stores, and from third-party suppliers like 3PL (third-party logistics) firms and drop-ship locations. This helps with inventory planning.

Next, the OMS provides fulfilment via robust order capture, validation and release; pick, pack and ship functionality including drop-shipping; shipment confirmations and customer communication.

After the order, a full-featured OMS enables easy payments and shares that data with financial systems. Should the customer wish to return an item, the OMS sets rules for processing returns from all channels, fulfilling exchange requests, crediting the customer account and managing the dispositioning process.

5 Ways to Reduce the Cost of Returns

Recovering as much income as possible on returned merchandise is critical. Here’s how.

Retrain the sales team and partners. If an item is returned more often than expected, look at how the sales team is selling it and how marketing positions it. Often, nothing is wrong with the item itself—it’s just being sold to the wrong customers or for the wrong uses.

Standardise returns processing. Returns must be handled immediately and efficiently to recover as much value as possible. Include return labels in shipments so your team can track packages, plan for their arrivals and inspect them quickly. All returns should be scanned or entered into your inventory/order management system upon arrival. From there, have documented processes for inspecting and restocking to minimise both shrinkage and the cost of reverse logistics—moving products back to the merchant from the consumer.

Don’t make immediate payment. Companies are often too quick to give clients full refunds before checking for damage, missing parts or anything else that could impact its resale value. All returns should go through a thorough inspection.

Augment online product content. The problem of returns starts at the checkout, especially with online purchases, where the buyer cannot touch the product. Mitigate this by offering more content: Multiple images, videos, detailed product descriptions and a Q&A section all contribute to lower return rates.

Consider outsourcing returns. Handing off returns to a third party could reduce costs. A 3PL (third-party logistics) firm brings to bear expertise and economies of scale, including better rates with carriers and more efficient processes tuned to the unique demands of the reverse supply chain.

Types of Order Management Systems

Companies can buy OMS software as individual modules covering different aspects of order management or as a complete suite that manages the entire process. A la carte modules sometimes provide tools that you can use to link them to other business systems, but this requires integration.

OMSes may also be onsite software or delivered in SaaS/cloud model, with the benefits of SaaS: faster and easier deployment, operating versus capital expense with “pay as you grow,” better scalability and access from anywhere there’s an internet connection with a browser or mobile app. Plus, the vendor maintains and hosts the application, which means a superior UX and better reliability.

In North America, beginning in 2021, IHL says SaaS/cloud OMS sales will outstrip legacy software sales, with the gap only widening from there.

#1 Cloud ERP

Software

How to Choose the Right OMS

Choosing the right OMS for your business is an important decision. Assess your current business needs while also thinking carefully about your company’s future requirements, taking into account expectations of business growth, global expansion, increasing order volumes and expanding sales channels.

It’s also important to consider connectivity to other systems, including your company’s ecommerce website and enterprise resource planning (ERP) system. Again, the fewer integrations and manual input, the less chance for error and downtime.

Cloud/SaaS OMS solutions don’t require that you maintain hardware or install software. On-premises OMS applications are available for companies that prefer to host and manage their own systems.

Look for support for complex processes, such as split shipments, drop shipping and personalisation. When fulfilment issues happen, you want to be able to quickly resolve them and let the customer know the status in real time. Does the OMS have mobile apps so that employees can access order status when working remotely or when interacting with customers face-to-face on site? After all, the bottom line is a happy customer who will order again from your company.