Think of modern integrated business planning, or IBP, as a mashup of supply chain optimisation, financial planning and analysis (FP&A) and operational best practises, powered by a companywide culture that’s all about delivering the speed, savings and responsiveness today’s consumers demand while managing risk.

Note that IBP as a fuzzy, buzzword-laden process methodology has been around for years. It’s usually implemented by expensive consultants in sprawling, global corporations that know they need to unify siloed sales, supply, financial and operational resources — before more nimble competitors relegate them to the former Fortune 500 list.

We’re here to argue that IBP deserves a second look for any company that wants to maximise profits and minimise the risks associated with growth. No six-figure consultant required.

What Is Integrated Business Planning?

On paper, IBP is a process for aligning a company’s business goals with its finance, supply chain, product development, marketing and other operational functions. Think parts suppliers that work with automakers and need to constantly retool to accommodate design changes, or food producers operating on razor-thin margins that must manage both uncertain supply chains and fickle customer tastes.

Lag, and a competitor is standing by to take that business. Move quickly but in a disjointed manner and you may keep customers, but at the expense of higher cost of goods sold (COGS)(opens in a new tab) and lower profitability.

For example, consider PickerBots, a fictional maker of custom machinery for manufacturing and warehouse operations. When the company launched in 2017, it found a niche in restaurant supply, but when that business slowed significantly in 2020 the founders decided to retool. Rather than simply changing up its marketing, the firm set out to revamp its business strategy. A top-down scenario planning exercise led to realigning its R&D, demand forecasting, profitability and revenue analysis, supply chain planning and marketing and sales strategy.

The company culture was already strong on innovative thinking, but the founders realised that the link between strategic planning and day-to-day operations could use improvement. Enter a new COO with the chops to align operations with product demand planning and sales and marketing while weighing in on financial targets and budgets.

Key Takeaways

- In a company that embraces IBP, there’s a direct line from purchasing, production and inventory to sales and marketing to financial targets and budgets.

- A key IBP benefit is that materials are bought at the right price, at the right time and in just the right quantity to fulfil market demand.

- Successful IBP delivers closer collaboration and more trust among departments, leading to improved decision-making.

- IBP may require significant cultural change and cannot be successful without unwavering commitment from the executive team.

Integrated Business Planning Explained

Many organisations mistake IBP for a supply-chain-centric exercise. While linking supply chain planning with other departments, from sales and operations through finance, is important, that’s just one element.

IBP aligns business goals and financial targets with decisions and execution across the entire business.

There is overlap with financial planning and analysis (FP&A). Because an IBP initiative gathers data from across the enterprise, companies get better at predictive analysis. Now, when purchasing forecasts a parts shortage, supply and operations can adjust before customers are affected.

It’s also not a one-and-done exercise. PickerBots’ new COO advises looking a minimum of 36 months out. Leaders will need to keep their eyes on that long-range plan while continually reviewing, revising and communicating financial and operating results. What supply chain gaps have opened up, and how can we close them? Do we need to update our scenario planning? Are we tracking the right financial KPIs?

A crucial element of IBP is that it integrates financials with operations. Here’s a structure that PickerBots plans to follow.

Why Is Integrated Business Planning Important?

Companies that undertake IBP realise a number of practical benefits, including reduced holding costs, more responsive customer service and demand fulfilment, shorter time to market for new products and an improved correlation between demand planning and fulfilment.

After PickerBot’s scenario planning and strategy session, the company decided to jump into the emerging collaborative robot, or cobot, market. A collaborative robot is designed to safely interact with human workers. PickerBot’s leaders believe demand will increase for “pick and place” cobots with fine motor skills for use on manufacturing lines as well as in agricultural settings.

Now that the company has its strategic direction, the COO wants to focus on three higher-level concepts before delving into more practical areas, like financial planning and analysis and supply chain optimisation. That’s because without goal-setting, PickerBots won’t be able to define success.

Alignment and accountability

All executives must agree on three things: What are our corporate goals? What does success look like for each? How will I and my team contribute and be accountable?

The company’s goals are grouped into four areas: industry-focused, operations and supply chain, financial and marketing and sales. The management team will review all goals to make sure they align with strategy and are both actionable and achievable.

Examples:

Industry-focused goal: Offer the most innovative cobots on the market

What success looks like: Develop a product that can match or exceed a human worker in its ability to pick fragile crops without damage.

Who will execute: The R&D team

Financial goal: Diversify revenue streams

What success looks like: Minimise dependence on one market/industry. Add a services arm to generate recurring revenue from maintenance contracts, powered by sensors built in to all new products.

Who will execute: Cross-functional led by CEO and finance

Other goals might be “control costs at each step and deliver cobots to customers on time and to specifications” with an expectation to lower COGS by 10% and raise the company’s Net Promoter Score by 25% within one year. Or for sales, “find 10 new customers for the company’s agricultural cobots and bundle maintenance contracts with each sale.” That ties back to revenue diversification.

An important point: Every manager is accountable for every goal, not just those that lie within their purviews.

Informed decisions and actions

Planning across PickerBots’ supply chain was disjointed, with engineers purchasing materials direct and little central planning or cost control. As part of the IBP process, the company will adopt sales and operations planning (S&OP) principles to improve its supply chain and logistics.

Actionable goals here include building visibility into how each department is working and tying the impact of decisions to financial goals. For example, by having R&D build in sensors that can automatically collect and transmit data on a cobot’s operational status, PickerBots can proactively perform preventative maintenance so the devices are almost never down — an important selling point and a way to contribute to maintenance income.

Organisationwide, divisions need to focus less on their own needs and view actions through the lens of all goals. That means the company needs to collect a lot of timely data and use it to issue reports so managers can make better decisions, more quickly. That may require an investment in ERP and other software.

Transparency/visibility

All department heads will take part in a monthly business review, where the group will assess progress in achieving the company’s objectives. The strategic plan is also available to all staff members, and quarterly all-hands meetings will be held to gather ideas and insights and walk through KPIs.

Four success metrics for the IBP process include:

1. Getting all stakeholders to buy in to corporate goals so that everyone agrees and understands what the business wants to achieve and how it will get there. There are clear responsibilities for each function in the pursuit of goals.

2. Basing business decisions on data. The integration of finance into product, demand and supply functions is key here, as are selecting the right KPIs.

3. Tying decision-making to outcomes and improving accountability. Because every department is responsible for providing accurate numbers and projections, there’s less risk that the CFO and finance team are left holding the bag if revenues fall short.

4. Shifting the culture to embrace cross-functional collaboration. An IBP process encourages openness and trust, and as a result more deeply engages and empowers employees. As an action item, each R&D and manufacturing team member will spend a week annually accompanying sales reps on customer calls.

What Is the Difference Between S&OP and IBP?

The term “IBP” was coined by management consultancy Oliver Wight to describe the next iteration of the sales and operations planning (S&OP) process Wight developed in the early 1980s.

The big difference between IBP and S&OP is that the latter has become the domain of supply chain and logistics specialists, particularly those involved in supply-and-demand balancing and planning. S&OP is execution-focused and involves a traditional budgeting process.

In contrast, IBP takes a more cross-functional and holistic approach to weaving business goals through every function. As a result, in theory, supply chain management is proactive and optimised.

IBP includes S&OP processes but because it involves cultural change, without executive buy-in, IBP will not be successful.

Some major differences between S&OP and IBP are:

| S&OP | IBP |

|---|---|

| Supply-and-demand focused | Involves the entire business in the planning process |

| Meetings-heavy and output focused | Monthly planning focuses on optimising results and leverages scenario planning as a tool. The result is a more agile organisation |

| Short-term plans to drive supply and output | Long-term view to inform decision-making |

| Traditional, static budgeting practises | Comprehensive and “living” financial plan with a range of associated KPIs |

6 Steps in the Integrated Business Planning Process

Now that its goals are set, PickerBots can take the next steps in its IBP journey.

1. Determine what is holding the company back. Is it a lack or growth or profitability? Is the product portfolio too complex? Has the business lost competitiveness in its space? For our manufacturing firm, the main problem was overfocus on one niche market.

2. Engage and educate employees. Once leadership buys in to goals, that enthusiasm must trickle down through the ranks. Unless everyone is committed to integrated business planning, success will be elusive. The COO recognises that a formal employee engagement program(opens in a new tab) will keep workers invested in the success of the business and actively working to meet strategic goals.

3. Set up a tiger team. IBP success comes from tight coordination, constant communication and accountability for KPIs. It’s a cultural shift that will take time to propagate throughout the business. To jumpstart things, PickerBots identified engaged employees within each functional area and assigned them to a daily 20-minute standup call. Now, say a shipment of RFID readers needed by manufacturing will be two weeks late. The purchasing team member shares that information promptly so that sales can manage customer expectations and finance can account for delayed revenue. If the problem recurs, the company can seek out new suppliers. No more surprises.

4. Establish a project/product prioritisation process. IBP takes discipline. Only projects that forward the company’s strategic goals get resources. Same for products. That might mean sunsetting a line that’s still selling but lacks growth potential. All managers who require resources or have a product or service launch idea fill out a cost-benefit analysis template that is tailored to reveal whether expected benefits and costs align with goals. Leadership prioritises using this process. No more sacred cows.

5. Expand the finance team’s influence. Finance needs to sit in on product planning, supply chain optimisation and sales strategy meetings. Specifically, choose a finance team member well-versed in FP&A functions. FP&A professionals inform major decisions made by the executive team and collect and analyse financial data from across the organisation to create reports that reveal whether goals are being met — and if not, why not? How do we fix the problem? Like many smaller firms, PickerBots doesn’t have a dedicated FP&A staffer, so the head of finance assigns an accounting team member who knows the business and has an aptitude for data collection and number crunching.

6. Adopt technology and tools to support IBP. If the forecasting process is seen as a quarterly or annual exercise imposed by finance and yielding little benefit to departments, IBP can’t succeed. Companies with static, point-in-time budgets need to adopt rolling forecasts(opens in a new tab) to make sure the business stays on track. And, finance teams need to be able to easily access the data they need from each operational area. Both rolling forecasts and better use of data require technology and a commitment to transparency. You can’t manage what you can’t measure.

Traditional vs. Rolling Forecasts

| Traditional Forecasting | Rolling Forecasting |

|---|---|

| Fixed financial plan calculated for a set period of time, typically one year, that uses historical observations to estimate future business metrics. | A “live” financial plan that is regularly updated throughout the year to reflect changes. |

| Calendar-based (annual, quarterly) | Event-based with real-time adjustments to calendar forecasts |

| Fixed targets (sales/profit, other KPIs) | Dynamic adjustments to targets based on external/internal events |

| Resource allocations are rigid | May trigger reallocation of resources based on dynamic targets |

| Manual, account-based and often linked to accounting cycles | Business-driver-based and connected to operations |

5 Tips to Succeed at Integrated Business Planning

Some ways the COO plans to set PickerBots up for success include:

1. Sell IBP as a way to bring order from chaos. For example, large companies, especially those that have engaged in a number of mergers and acquisitions, may have thousands of SKUs and product codes. One big manufacturer Oliver Wight worked with used IBP to whittle 120,000 item numbers down to about 10,000 and reduce inventories by 50% while improving on-time, in-full delivery by up to 20%. For a smaller company, IBP can prevent ever getting in a situation where it needs to slash 90% of SKUs.

2. Adopt a continuous improvement mindset. All parts of any production or service system, particularly people, are interconnected, inform one another and are mutually dependent on generating successful outcomes. This practice’s origin comes from Kaizen, a Japanese term meaning “change for the better.” Originating in Japan, the business philosophy looks to continuously improve operations and involve all employees, from assembly line workers to the CEO. It’s a way to reinforce IBP.

3. Get buy-in from the CIO. PickerBots’ CIO came up through the ranks of manufacturing IT and is familiar with the concept of Total Quality Management (TQM), which has overlap with IBP. That went a long way in communicating the benefits of IBP and freeing up budget for technologies that can make IBP work, like ERP, enterprise performance management (EPM), supply chain management and real-time-capable accounting and finance software — especially important to realise the “one set of numbers” value proposition.

4. Apply risk management principles. Disasters large and small happen. While the zen of IBP skews toward positive and upbeat, make sure department heads are doing scenario planning and what-if analyses to model operational risk — like overdependence on one market. Consider assigning your tiger team a secondary function as a crisis management strike force(opens in a new tab).

5. Don’t forget HR. Labour is likely your company’s biggest operating expense, so ensure that it’s working for your IBP effort, not against it. A human resources professional can identify traits in applicants — like team players who are data driven and comfortable with transparency — that predict whether they will be contributors to IBP success.

Benefits of Integrated Business Planning

Research shows that the main benefit of implementing IBP is increased revenue, followed by forecast accuracy and improved Perfect Order Delivery rates.

Three additional key benefits:

Real-time insights: Once companies have instituted rolling forecasts, for example, finance can more quickly and accurately answer questions on spending and cash flow. Expect more accurate KPIs across the board.

Ownership: The flip side of accountability is that in a company fully embracing IBP, all employees assume responsibility for meeting all goals. So you’d better make sure that authority to make decisions is decentralised and tied to responsibility for outcomes, because there are few bigger morale killers than accountability without the power to effect success. Companies can further nurture a culture of ownership by tying rewards to meeting or exceeding goals.

Improved customer satisfaction: While more on-time, in-full deliveries make customers happy, that’s not the only way IBP improves Net Promoter Scores. Better planning yields better insights into what customers want, and a strong company culture often leads to improved customer empathy(opens in a new tab) and its associated benefits.

Integrated Business Planning Adoption Challenges

Where a business starts with IBP depends on its maturity. Companies with dog-eat-dog cultures and highly siloed processes have a lot of work to do. These tend to be firms with traditional top-down management structures, static annual budgeting with little ability to generate forward-looking projections and dated business plans that are misaligned with current customer needs.

While all are thorny structural challenges, a leadership team that’s averse to placing trust and decision-making authority at lower levels of the organisation is in even worse shape. Companies with autocratic, command-and-control styles must be willing to decentralise authority if they hope to realise IPB’s benefits.

Even businesses with mature, integrated processes and egalitarian cultures often get tripped up by “top down” versus “bottom up” KPI reporting and budgeting. IBP requires businesses to focus less on finance developing a top-line budget and then handing departmental budgets down from on high. Rather, they need to become comfortable with a bottom-up process, where departments start with a plan of what they want to achieve, calculate what it will cost and then feed a number up to the finance team, which uses that input to calculate the total budget.

Companies not already using at least a somewhat flexible budgeting process are likely to find this shift difficult. One way to jump-start the transformation might be a modern form of zero-based budgeting(opens in a new tab).

Steps of Zero-Based Budgeting for 2023

- Create a strategic vision for ZBB: Identify cost targets, relevant KPIs and goals.

- Evaluate business units to select ZBB candidates (also referred to as “decision units,” or any organ of the business that operates independently with its own budget).

- Start selected budgets from scratch (i.e., from zero).

- Each decision unit provides “decision packages,” which break down each activity in terms of its objective, funding needs, justification in the context of company goals, technical viability and alternative courses of action.

- Evaluate each proposed item to determine its value-add to the company and whether the entire cost is justified. What does the expenditure bring back to the company?

- Prioritise costs based on company goals. Reduce or cut expenses in areas that no longer produce significant value.

- Allocate funds among areas that are productive and aligned with the business’s growth drivers.

Elements of Integrated Business Planning

Integrated business planning takes place at a regular cadence; every month is most common, so we’ll use that in our example.

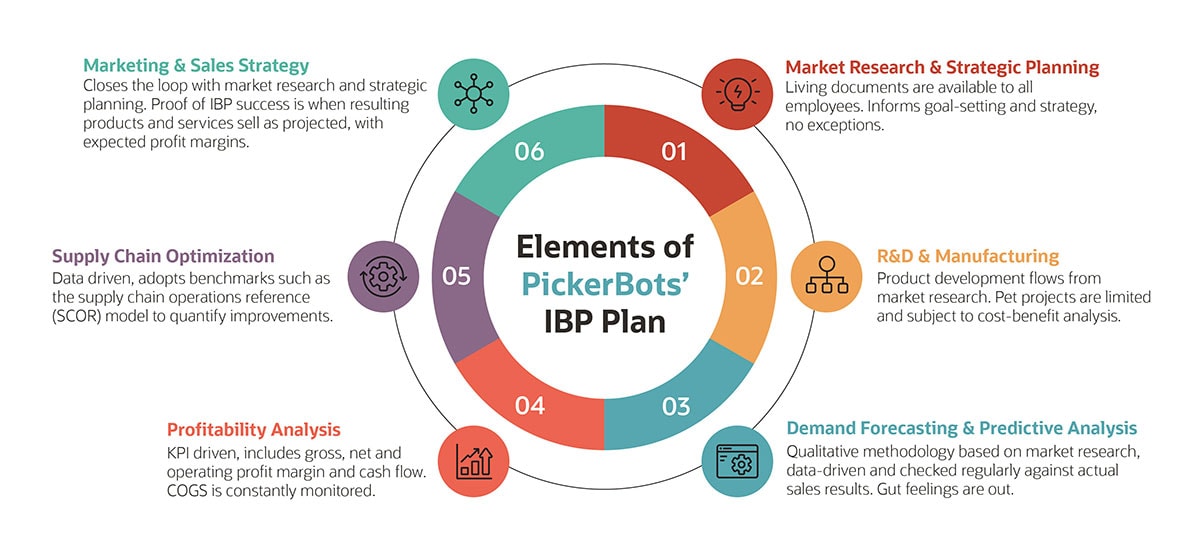

These steps are standard for IBP consultants, adaptable to most industries and bake in the PickerBots COO’s virtuous cycle of market research and strategic planning, R&D and manufacturing, demand forecasting and predictive analysis, profitability analysis, supply chain optimisation and marketing and sales strategy.

1. Product management review. This includes all elements of product portfolio management. A cross-functional team meets monthly to review the overall status of all of product-related projects: Are they on track? Have we identified new risks and opportunities? Are the most high-value products or services prioritised? The goal is aligning the product portfolio with business goals and making sure needed raw materials and manufacturing floor capacity are lined up. Product managers revise as needed and publish an updated master plan, along with the resources it’ll take to deliver any changes.

2. Demand planning picks it up. This is a cross-functional process that helps businesses meet customer demand for products while minimising excess inventory and avoiding supply chain disruptions. Demand planning(opens in a new tab) can increase profitability and customer satisfaction and lead to efficiency gains. This team brings together members of sales, marketing and finance to determine whether they’re targeting the right markets, the right way. They work up an optimised demand plan. Relevant KPIs include sales forecast accuracy, inventory turns, fill rates and order fulfilment lead times.

3. Then, the ball goes to the supply planning team. These supply chain experts work out the optimal way to meet projected demand in a cost-effective way. The key is to have visibility into complex supply chains; a formal supply chain visibility (SCV) project helps spot and fix weaknesses, such as inventory shortfalls or order fulfilment issues, before they become major problems. Lower cost of goods sold (COGS) is the North star.

4. The integrated reconciliation team pulls together the initial product, demand and supply plans and consolidates them into one holistic business plan based on a 24- or 36-month projection; for iterative updates, teams highlight material changes. Decisions that could not be made by individual teams are prepared for executive review.

5. The executive team resolves conflicts and rolls the updated plan out to the entire company.

Integrated Business Planning Components

The components of integrated business planning comprise three buckets: Plan, execute and monitor and adjust.

Specific actions falling into each bucket vary depending on the consultancy or technology supplier. Some are more aligned with supply chain planning(opens in a new tab), while others center on S&OP or financial planning with plug-ins to other functional areas. Others are very industry-specific.

Let’s look at Oracle’s IBPX (Integrated Business Planning and Execution) for Manufacturing solution as an example. Key components include:

- Top-down and bottom-up, driver-based planning and forecasting

- Risk modelling for M&A and strategic initiatives

- Full financial statement structure for strategic and operational planning

- Predictive and prescriptive analytics and planning

- A preseeded S&OP process

- Near-real-time demand and supply balancing

- Real-time backlog management

- Automation of predictions and correction actions based on actuals(opens in a new tab)

- AI-enabled operational planning, such as for sales territories and quotas

- IoT and sensor data flows integrated with automated decisions

Items like backlog management and enhanced support for IoT and sensor data are important to manufacturers like PickerBots. A retailer might be more interested in advanced inventory management. What’s important is that any solution, whether purchased as a suite or pulled together by an integrator or in-house team, supports the ability to do long- and medium-range and short-term planning based on a single, up-to-date data set that’s accessible to all authorised stakeholders.

Also look for the ability to easily model “what-if” scenarios, robust budgeting and costing and a roadmap to advanced technologies like AI and predictive analytics.

Integrated Business Planning Examples

We mentioned the Oliver Wight customer that whittled 120,000 SKUs down to about 10,000. That firm, Uponor Group, looked to IBP after a string of acquisitions left it with swelling inventories, an extremely complex portfolio and a lack of communication between siloed functions and far-flung locations. The Finnish company sells products for drinking water delivery as well as radiant heating and cooling equipment and has 3,900 employees in 30 countries. Uponor had a hard time getting a singular view of financial information across its subsidiaries, and each unit had its own practises for inventory management. Small events, such as holidays, would drive some sites to build up “just in case” inventory, and double-stocking in warehouses was common. Subsidiaries in different countries had different SKUs for the same items, and R&D was localised, with no collaboration across the company.

Upinor focused first on its supply chain and implemented S&OP processes, then advanced to IBP the following year. The results have been an increase in net sales of $1.1 billion euros, a 30% improvement in on-time in-full deliveries, a 50% reduction in inventories and increased visibility.

U.S.-based technology provider Juniper Networks(opens in a new tab) also undertook an IBP project focused on implementing a digital supply chain with IBP, where the business planning process would extend S&OP throughout the supply chain, product and customer portfolios, customer demand and strategic planning.

Since undertaking the project, Juniper’s lead-time attainment is up 55%. and its inventory costs are down by 15%, allowing it to realise a positive ROI on the IBC project.

History of Integrated Business Planning

Oliver Wight developed S&OP in the 1980s as a methodology for a client that wanted to balance supply-and-demand volume. In the years since, the process evolved to integrate financials, inventory and new-product introductions.

The consultancy renamed S&OP as integrated business planning in the late 1990s to reflect the process of integrating all functions of the business behind one optimised plan. Since then, a newer term, “enterprise integrated business planning,” has emerged. EIBP includes scenario planning and extended supply chain collaboration and discusses how large companies will adopt new technologies, such as AI, big data and advanced analytics.

Applications of Integrated Business Planning

IBP makes planning and operations much more transparent, so it’s ideal for companies moving to “just in time” manufacturing. It’s also predictive, once a company builds up some data. That can help with customer satisfaction.

PickerBots, as an example, found that it typically sees constrained supply chain capacity for motherboards in Q3. With that insight, sales and marketing can work to encourage customers to take delivery of systems in Q2 or Q4, manufacturing can prebuild products and supply chain leaders can work on alternate sources for parts that pose challenges.

Looking ahead to the future of IBP, we expect it to help companies:

- Work on ever-longer-range strategy planning, modelling and M&A activities with a higher degree of confidence.

- Detect and notify stakeholders of unanticipated events before they impact the business by using advanced technologies, including real-time sensor information and machine learning (ML) pattern recognition.

As companies build comfort with automation, advanced IBP systems can be set to take action based on analysis without human intervention. Consider a chain of bakeries; a system plugged into a long-range weather forecast system might detect a tropical storm that could raise the price of vanilla and automatically order extra.

Cloud-based technology such as ERP underpins all these advances. For example, PickerBots always set its sales goals monthly. But often these plans were delayed to let the executive team review and approve any changes, meaning operations was caught unawares. A tool like NetSuite Planning and Budgeting automates planning processes and centralises company financial and operational data, so finance teams can disseminate updates quickly.

The next frontier? Expending IBP to business partners and suppliers, even customers. But first, companies need to get their own cultural and technology houses in order.

#1 Cloud

Accounting Software