Planning a warehouse is key to a business’s ability to effectively store, organise and manage its goods or raw materials. Without an efficient warehouse layout, time is wasted on simple day-to-day tasks, such as locating goods, navigating aisles and tracking inventory. This can result in increased operating costs and inefficient workflows that directly hinder the supply chain, preventing goods from getting to customers as quickly as possible. The best warehouse layout depends on a business’s needs, but any strategically planned facility will always maximise space, optimise productivity and prioritise safety.

What Is a Warehouse Layout?

Warehouse layout refers to how the space within a facility is arranged. This layout dictates how materials, workers and equipment move through the space, with the goal of optimising the flow of production and distribution. Specifically, warehouse layout considers how each area of the warehouse, including storage, picking, shipping and office space, is organised, as well as how necessary equipment is placed and used in these areas. Warehouse layout should also take into account the size and shape of items that need to be stored and any potential hazards or obstacles that could impede movement.

By understanding how to properly design a warehouse layout, companies can ensure that their operations run efficiently. An efficient warehouse design optimises the flow of products from one area to another while maximising space utilisation. Warehouse layout can directly affect a company’s profitability, so care should be taken in the design.

Key Takeaways

- A warehouse layout refers to how the facility’s internal and external spaces are arranged.

- Well-designed warehouse layouts optimise the storage, movement and retrieval of goods to boost operational efficiency.

- Warehouse layouts must take into account shelving, equipment, aisle space, the types of goods stored and worker safety.

- Five core components of a warehouse layout are receiving, storage, packing, shipping and office areas.

- Automated solutions, such as warehouse management systems, can help companies design and implement better warehouse layouts.

Warehouse Layout Explained

A warehouse layout is an organised plan for the efficient storage, retrieval and movement of goods within a warehouse. There’s no one-size-fits-all way to plan a warehouse; specific designs generally depend on a business’s needs. For example, different types of products demand different storage methods, which ultimately affects the final layout. Perishable goods(opens in new tab) might need to be stored in coolers or freezers, while non-perishable items can be stored on shelves. Dangerous chemicals present hazards and may require separate safe and secure storage areas, whereas pallets of materials, such as bricks or cinderblocks, can safely be stacked out in the open.

Workflow is another key consideration when planning a warehouse layout. Ideally, warehouses should be designed in a way that makes it easy for workers — or autonomous mobile robots (AMRs) — to move from one area to another. This includes making sure there’s adequate space between aisles not only for movement, but also for safely using equipment, such as pallet jacks and forklifts. In addition, it’s important to consider the logical flow of materials and goods, which involves both internal and external warehouse space. It might make sense to place the packing area between the internal storage area and the external shipping bay, for instance. A warehouse layout should also consider employee areas as separate from work areas, including ample space for staff to take breaks, eat and use the restroom.

Warehouse layouts are often used in conjunction with warehouse management systems (WMS)(opens in new tab) to ensure that goods are stored correctly and can be retrieved quickly.

Why Warehouse Layout Is Important

Warehouse layout can make or break an operation’s overall efficiency. Poorly designed warehouses can lead to issues, such as low productivity, lost or damaged inventory and even accidents. A smart layout is carefully planned to improve overall productivity and safety, enabling the business to move goods through the space in the most cost-effective way possible. Put simply, a well-designed warehouse layout can improve efficiency, reduce costs and improve customer satisfaction.

For example, if warehouse organisation impedes workers’ ability to effectively store, pick and pack goods(opens in new tab), time is unnecessarily wasted. The time that employees spend searching for misplaced items, dealing with mis-picks or simply walking more than necessary takes away from more productive tasks, such as preparing orders for shipment. An organised warehouse is easier to navigate, reducing employee travel time, boosting productivity and benefiting the company’s bottom line.

Carefully designed warehouse layouts can also be safer, and safety is a key concern for employees as well as customers. Ergonomic principles, such as placing frequently accessed items in easily reachable areas, can help minimise bodily injuries and strain. A well-designed layout also provides clear pathways for pedestrian and vehicle traffic, designates areas for hazardous materials and ensures that heavy equipment is used in a safe and controlled manner. As for customer impact, warehouses should be planned in a way that inhibits any chances of cross-contamination or damage to goods. In a food storage facility, for instance, it’s important to account for space that will prevent materials from being contaminated by insects or other pests.

Components of a Warehouse

There are a few key components that every efficient warehouse needs, regardless of size or industry. The placement of these components forms the backbone of the overall warehouse layout. At the same time, it’s also important to consider the layout within each component, as each affects the efficiency of the operation as a whole. Here are the essential components to plan and organise within a warehouse layout.

- Receiving area: Incoming shipments are unloaded, checked in and sorted in the receiving area. The receiving area is inside the warehouse and generally connected to a receiving bay on one side, providing direct access for trucks and vehicles transporting goods. The receiving area should be adjacent to the storage area to make it easier to move incoming goods to their appropriate locations.

- Storage area: Inventory is kept in the storage area until it needs to be picked to fulfil an order. The storage area should be well-organised and designed for accessibility, with direct connections to both the receiving and packing areas. Storage areas typically include pallet racks and shelving units, which are used to store inventory. An efficient storage area can help reduce travel time and improve order picking (opens in new tab) accuracy, as well as inventory management capabilities.

- Packing area: The packing area is where orders are packaged for shipping after being picked. Packing areas are typically directly connected to the storage area and the shipping bay. To help get orders prepped for shipping as quickly as possible, packing areas should aim to enhance speed and accuracy without sacrificing worker comfort and safety.

- Shipping area: Outgoing orders are prepared for shipment in the shipping area, which is essentially the inverse of the receiving area. The shipping area is inside the warehouse and generally connected to a shipping bay on one side, with direct access to the packing area on the other. Smart warehouse layouts account for space in the shipping area to wrap pallets and use equipment like pallet jacks and forklifts, as well as space to stage completed orders that need to be loaded onto a truck for distribution.

- Service areas: Service areas, such as restrooms, employee break rooms and management offices, support the day-to-day operations of the facility. Restrooms should be easily accessible to workers, and office space should be near the receiving and/or shipping areas, as managers will likely need to process invoices; connect with customers, suppliers and logistics companies; and manage other daily duties.

Depending on a business’s needs, a warehouse might also include other areas. For example, a high-volume warehouse might have a dedicated staging area between the receiving and storage areas that allows for more space to unbox incoming shipments, split pallets, conduct quality control checks and prep materials that need to be stored.

Warehouse Layout Considerations

Every business has its own unique factors to consider when designing a warehouse layout that meets its needs. A few considerations to keep in mind include the type of operation, the products being stored, equipment requirements, available space, workflow implementation, safety regulations and cost efficiency. Keeping these factors in mind can help a business design a warehouse that’s efficient and effective.

- Type of operation: The type of operation will dictate the flow of traffic and the type of storage needed. For example, a warehouse connected to a manufacturing operation(opens in new tab) will likely require a different layout than a distribution centre. A manufacturing operation might keep its storage area near the production room, as workers will need direct access to raw materials in order to produce final products. A distribution centre, on the other hand, likely deals with finished products and, therefore, will keep its storage area close to packing because there may be no production room.

- Products being stored: The products being stored will also dictate the type of storage needed. A small-scale hummus manufacturer, for example, might dedicate a section of the warehouse to dry goods storage (salt, spices, flour, baking soda, dry garbanzo beans), and another section to cold storage for perishable materials (lemons, garlic, cooked garbanzo beans, finished product). A large ecommerce warehouse, meanwhile, might house only non-perishable consumer goods, like clothing, electronics, toys and home goods, and won’t need separate cold storage and dry goods areas.

- Available space: Unless the warehouse is being designed and built from the ground up, available space will play a role in the warehouse layout design. Every inch of a warehouse should be used to its fullest potential. The size and shape of the building will dictate what types of storage and equipment can be used — for example, shelving and racking, carousels and automated storage and retrieval systems (AS/RS) — and where in the facility each can be located and used most effectively.

- Equipment requirements: Racking and shelving systems come in a variety of shapes and sizes and can be customised to best fit the types of products being stored and the way they’re stored. They’re essential to increasing storage density, maximising space utilisation and creating a highly organised environment. The use of material handling equipment, such as forklifts, pallet jacks, conveyors and AMRs, also depends on the types of goods stored and how they’re stored, as well as the size and overall layout of the warehouse and overall workflow.

- Workflow implementation: The layout of a warehouse impacts how goods, personnel and equipment move through the warehouse and the efficiency of those movements. By designing a layout that supports the workflow and minimises bottlenecks, a warehouse can improve productivity and reduce errors. For example, the layout of the warehouse can determine the right order picking type for a business. Zone picking(opens in new tab) might be more effective in a large warehouse with several discrete storage “zones” of many different SKUs, whereas wave picking(opens in new tab) can prove more useful for warehouses shipping fresh goods that can’t sit out for long periods and, therefore, need to be picked just before shipping.

- Safety regulations: Warehouses must adhere to a variety of safety regulations, enforced by the Occupational Safety and Health Administration (OSHA). Some requirements to consider when planning a warehouse layout include creating defined exit routes in case of emergency, designating locations for portable fire extinguishers and ensuring there’s safe clearance in aisles and at loading docks.

- Cost-efficiency: In the warehouse planning process, companies might sketch out several different layout plans, ranging from the most basic to the most comprehensive and advanced — there’s no limit to the design process. Though a robust warehouse layout might be tempting, it’s important to carefully assess the budget and business requirements to determine what layout will balance cost with operational goals.

7 Steps to Plan the Perfect Warehouse Layout

There are seven major steps required to plan the perfect warehouse, from defining the operation’s overall purpose to testing and implementing the layout.

- Define the overall purpose of the warehouse. What is the business model and objective of the warehouse? For example, is the warehouse designed to support a manufacturing operation, a distribution centre or a big box store location? What will be stored in the warehouse, how much inventory will be maintained and how will products move into and out of the facility? The answers to these questions will help the business create a layout that will genuinely expedite operations without sacrificing quality.

- Create a warehouse diagram and calculate total storage area. An effective warehouse layout starts with an accurate 2D visualisation, no matter the size of the space. This can be done manually using grid paper or digitally through design software. Accurately measure and assess the total available space by determining its dimensions, including floor space and ceiling height. Include doors, stairways and beams, and subtract the area of any restrooms, offices, boiler rooms and other parts of the warehouse that can’t be effectively used for storage. Knowing the total cubic volume of the storage area is critical to figuring out how to optimise the space available.

- Consider storage requirements. Decide what types of storage are needed to house the business’s inventory most effectively — for example, shelving, pallet racks or a combination of the two. Will items be stored on pallets, in bins or stacked? Don’t forget to estimate how much inventory will be stored at any given time. Warehouse management systems may be able to calculate the total volume of all products stored in the warehouse. Compare this number to the total available storage space to determine storage requirements. Knowing these metrics helps establish limits on how you store products and lets you know when your warehouse is approaching full capacity.

- Evaluate material handling equipment needs. Identify which types of material handling equipment(opens in new tab) is best suited for the items being stored. Will a pallet jack and a simple forklift do, or do the warehouse’s inventory and processes warrant more advanced equipment, such as carousels, conveyors or AS/RS? Although these pieces of equipment may be helpful to pick and put away items, they take up varying amounts of space. The larger the equipment, the more it begins to chip away at potential storage areas — forklifts, for example, require more aisle space than pallet jacks.

- Map it out and optimise space. Build on your warehouse diagram to develop a blueprint for the warehouse layout, taking into account the space requirements and storage and equipment needs outlined above. Remember, the overall goal is to figure out how to optimise space. To do so, it’s important to create as accurate a model as possible, using either grid paper or software. Plot the flow of goods from the moment they enter the warehouse in the receiving area to the moment they’re loaded onto trucks in the shipping area. Pay close attention to any spaces that could create bottlenecks and impede workflow.

- Test traffic flow. Put the proposed layout into action. Establish aisles and pathways in the open warehouse space, using masking tape on the floor to mockup a warehouse layout and walk through it. If possible, carry boxes around, move pallets and drive a forklift. Ensure that spacing is adequate and safe, and make any adjustments before installing racking, shelving and other major equipment.

- Implement the layout. Put shelves, racking and any other required equipment in their respective locations. Mark out storage areas and traffic lanes, using clear signage. Logically place materials and products in designated locations, keeping them clearly labeled so they can be found quickly. Train employees on processes and procedures, including safety training that meets compliance requirements, as well as maintenance plans that will keep the warehouse in top shape.

Once the warehouse is up and running, it’s important to regularly review processes to ensure optimal efficiency and address areas in need of improvement. And continue to assess and refine workflows as the business expands or evolves. For example, a warehouse transitioning from batch picking(opens in new tab) to zone picking might decide to start storing items in any open space within an assigned pick zone instead of in a permanent inventory location — a process known as random warehouse slotting(opens in new tab).

3 Warehouse Layout Design Types

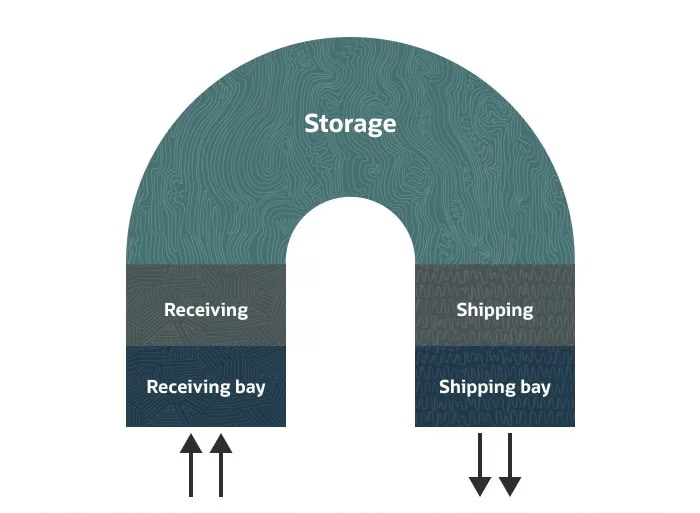

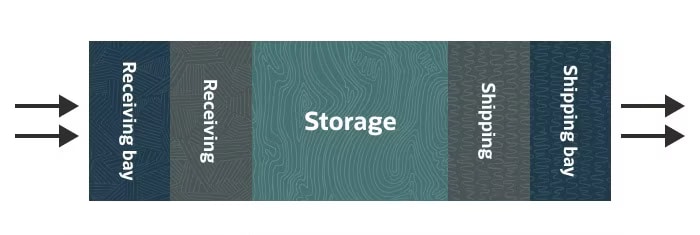

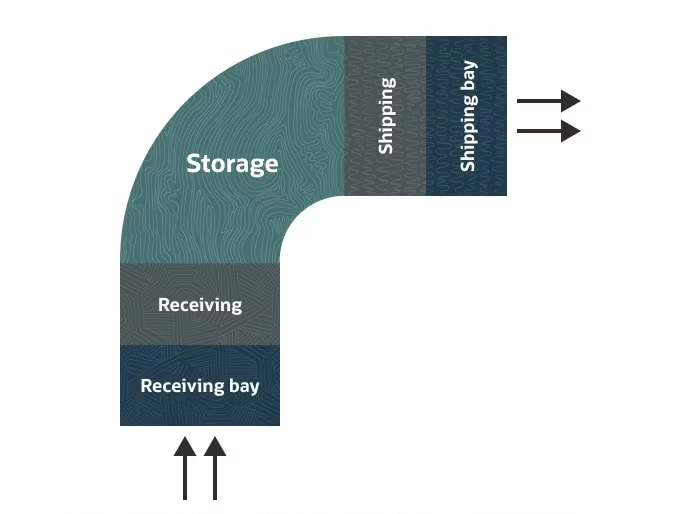

Most warehouse layouts use one of three common design types: U-shaped, I-shaped and L-shaped, each of which can drive efficiencies. The best one depends on the space available and the workflow needs of the business.

U-shaped: This warehouse design is laid out in the shape of a semicircle, or a “U.” Receiving and shipping are adjacent to one another on either end of the “U,” and storage fills out the back of the warehouse. This design is typically better for small buildings, but truck congestion can occur if the shipping and receiving bays are too close to each other.

I-shaped: This warehouse takes the shape of a straight line, like an “I.” Shipping is on one end, receiving on the other, with storage in the middle. All goods move in a single direction like an assembly line. This straightforward design can be useful for warehouses that deal with high-volume orders.

L-shaped: This warehouse design follows the shape of a 90-degree angle, or an “L.” Shipping and receiving bays are at either end of the “L,” with storage in the corner. L-shaped warehouses can be useful for businesses that cross-dock, or quickly transport items from an inbound truck to an outbound truck. Cross-docking is common in companies that rarely stock products on racks and quickly ship stock after it’s received.

5 Warehouse Layout Design Best Practices

Though the specifics of a warehouse layout depend on the business’s needs, there are five core best practices that all companies should bear in mind when designing a warehouse: maximising space, improving accessibility, accounting for change, using technology and prioritising safety.

- Maximise space. Using available space to its fullest potential sometimes requires thinking outside the box. Adjustable racking and shelving systems can greatly increase vertical storage capacity, as well as provide greater flexibility in how inventory is stored. But if it’s safe to stack pallets of certain items, stacking can be a more efficient use of space. The need for fewer racking units can also save money. Similarly, widths should allow for the safe operation of material-handling equipment, but not so wide that they reduce the overall storage capacity of the warehouse.

- Improve accessibility and visibility. To facilitate a smooth workflow, it’s important to ensure a clear path from receiving to shipping and that all storage areas in between are easily accessible. Appropriate lighting, signage, labels and color-coding systems can make it easier for workers to locate inventory, reducing frustration and potentially cutting labour costs. More advanced warehouse management systems might incorporate assisted-picking solutions, such as pick to light systems — which use lights and LEDs on racks or shelves to indicate pick locations — and voice picking technology(opens in new tab). Both can make it easier for pickers to find the inventory they need, when they need it.

- Account for change. An efficient warehouse layout ensures that the spatial arrangement will hold up over time, including providing the flexibility to accommodate company growth. Plan for ways to free up space for new products and processes — for example, by saving specific shelving areas for order fluctuations. Monitoring trends and consistently evaluating operations can help a warehouse stay agile.

- Take advantage of technology. A wide variety of technology solutions exist to help a warehouse get the most out of its layout. Warehouse management systems and inventory management systems, for example, can support every aspect of a warehouse’s operations, from tracking inventory locations and quantity to generating efficient picking routes and tracking essential key performance indicators (KPIs)(opens in new tab). Other technologies, such as AMRs and conveyor systems, can help reduce manual labour, while mobile scanning devices and radio frequency identification (RFID) technology can boost inventory accuracy as goods are moved throughout the warehouse.

- Design with safety and cleanliness in mind. Keeping all warehouse spaces clean and free of clutter creates an environment that’s safer and easier to work in, while reducing the chances that items are misplaced or lost. Potential hazards should be identified and eliminated, and the layout should allow for safe work practices to be followed at all times. Safety hazards are, at best, OSHA violations. At worst, they risk the well-being of employees. In addition, warehouse staff should be trained adequately. Comprehensive training should include occupational hazard awareness training, as well as how to safely operate equipment, manage inventory and handle shipping and receiving procedures.

Warehouse Layout Challenges

Challenges can arise when designing a warehouse layout, the most obvious of which is figuring out how to put the puzzle pieces together to create a truly efficient space that enables smooth operations. Deciding how to maximise space requires a lot of time, calculation and experimenting with different possible arrangements. To create a cost-effective layout that doesn’t sacrifice efficiency, careful budgeting is necessary.

Structural issues can also present a challenge. For example, if a company purchases a warehouse, but the current building’s shipping and receiving bays are too close together, inbound and outbound trucks might interfere with one another, creating bottlenecks. Or, if the warehouse was not leveled well, pallet jacks, carts and other wheeled equipment might be prone to rolling and getting in the way of workers, autonomous robots or forklifts, potentially causing safety hazards.

For warehouses planning to implement physical and/or digital process automation, just getting these systems up and running can be complex and costly. Automating a warehouse requires its own plan, project schedule and consultations with experts. But this upfront time and cost investment is vital, especially considering that physical automation systems, such as AS/RS, require specific warehouse layouts to be successful.

Finally, safety and compliance requirements are always a challenge. Warehouses can be dangerous working environments that require heavy machinery and repetitive physical motions that can cause strain over time. Goods are also often stored high on shelves, posing a risk of falling objects, and some warehouses store hazardous materials, which have specific handling and storage requirements. Proper worker safety protocols that meet industry-specific regulations and standards, as well as general health and safety standards, must be enforced to create a better working environment for employees.

Improve Your Warehouse With the Perfect Layout and Automation

Designing the perfect warehouse layout is a complex process that can be made much easier with the right technology. NetSuite Warehouse Management System(opens in new tab), for example, can be used to find inefficient uses of space and suggest different, more effective layouts. The WMS can also be used to identify optimal storage locations for different products and to identify more productive picking and packing routes.

Even in the best-designed warehouses, managing the overall workflow is a complex and often tedious process. NetSuite WMS can help there, too, using automation to monitor inbound and outbound shipments, manage employee tasks and track and monitor inventory in real time. These day-to-day enhancements can boost productivity by making sure the company is using its warehouse layout to the fullest.

A well-designed warehouse layout is essential to any business looking to efficiently ship products and cut back on unnecessary costs. But planning a layout is a complex process that involves carefully organising space, equipment and personnel — without exceeding a predetermined budget. Maximising available vertical and horizontal space, improving accessibility, planning for change, using the right technology and prioritising worker safety can help any business create an efficient warehouse layout that meets its unique needs.

Warehouse Layout FAQs

What is the layout of a warehouse?

The warehouse layout refers to the arrangement of space within a warehouse. Layout includes factors like aisle widths, shelving and racking arrangement and the location of internal and external warehouse components, such as the receiving area, storage area, packing area, office area and shipping and receiving bays. A warehouse layout is important because it directly impacts workflow efficiency, operating costs and employee safety.

What is a product-oriented warehouse layout?

A product-oriented warehouse layout is a type of warehouse arrangement in which finished products are stored in specific locations according to their type or product line. This type of layout is commonly used in warehouses that deal with a large number of SKUs, such as ecommerce warehouses and retailers. Conversely, a process-oriented layout carefully considers the process by which products are made, such as in a warehouse that directly supports an attached manufacturing operation.

What is a poor warehouse layout?

A poor warehouse layout is an arrangement that fails to optimally use the available space to receive orders, store materials, pick items, pack orders and ship them. Inefficient use of space can lead to higher operating costs, longer lead times and ultimately decreased customer satisfaction. Signs of a poor warehouse layout include bottlenecks, difficulty locating items on shelves and lack of room to safely navigate aisles.

What is the best warehouse layout?

There’s no one-size-fits-all warehouse layout. The best arrangement depends on the business’s needs and industry. However, some tips to design a best-in-class warehouse layout include incorporating efficient storage solutions, optimising space usage, prioritising worker safety, leveraging technology to improve operations and leaving room to adapt to changing business conditions or growth.

What should every warehouse have?

The precise needs of a warehouse depend on the company’s requirements, but every functional warehouse should strive to have:

- An effective and efficient layout that allows for easy movement of workers, vehicles and materials.

- A robust and reliable inventory management system and/or warehouse management system.

- An emphasis on safety, organisation, cleanliness and security.

- A team of skilled workers and managers.

How do I organise my warehouse layout?

To organise a warehouse, it’s important to consider the type of products being stored, how they’ll be stored, the space available and the number employees scheduled at any given time. Knowing these factors can help you organise your warehouse in a way that’s most efficient for your company’s needs. For example, a business that stores highly perishable goods would need to factor cold storage areas into its layout, whereas an electronics retailer would not.

Why do we need to lay out a warehouse?

Warehouse layout can directly affect a business’s productivity, operating costs and lead times — and ripple out to impact supply chain efficiency and customer satisfaction. Well-designed warehouse layouts use space efficiently, which can make it easier for workers to perform day-to-day operations, such as picking and packing. The more seamless a workflow, the faster orders can ship out to customers. Smart designs can also increase worker safety.