Companies with complex operations historically have compartmentalised the individual functions of their supply chain, handling each step separately in what is known as a siloed approach. Today, thanks to modern technology, many companies have big-picture visibility into their supply chain operations, from the procurement of raw materials and manufacturing through product delivery and post-sales services. Businesses with the ability to view their complete end-to-end supply chain can identify improvements and operate more efficiently than their competitors, especially in the highly competitive and customer-driven ecommerce world.

What Is an End-to-End (E2E) Supply Chain?

An end-to-end (E2E) supply chain integrates a business’s supply chain functions into one continuous workflow, from procurement of raw materials through delivery of finished goods to customers. This is in stark contrast to the series of loosely connected operations in a traditional siloed supply chain. An E2E supply chain focuses not only on the operations involved, but also on how they interact with one another to create a holistic view of a company’s supply chain, where each function is optimised in a way that emphasizes connectivity and integration. By having visibility across its entire supply chain, a business can identify optimisations to create a more streamlined and efficient operation, leading to cost savings, reduced waste and increased customer satisfaction.

Blockchain for End-to-End Supply Chain

End-to-end supply chains often require communication among several different parties, including suppliers, logistics service providers (LSPs), shipping agencies and more. Many companies use blockchain technology to maintain an open line of communication among all entities involved. This modern technology helps create a system of data exchange that is both secure and transparent. Blockchains also provide parameters that let parties share only the information necessary to create an efficient E2E supply chain and maintain data security.

Key Takeaways

- End-to-end (E2E) supply chains integrate a business’s operations into a continuous workflow by analysing all steps in the supply chain and how they interact and influence one another.

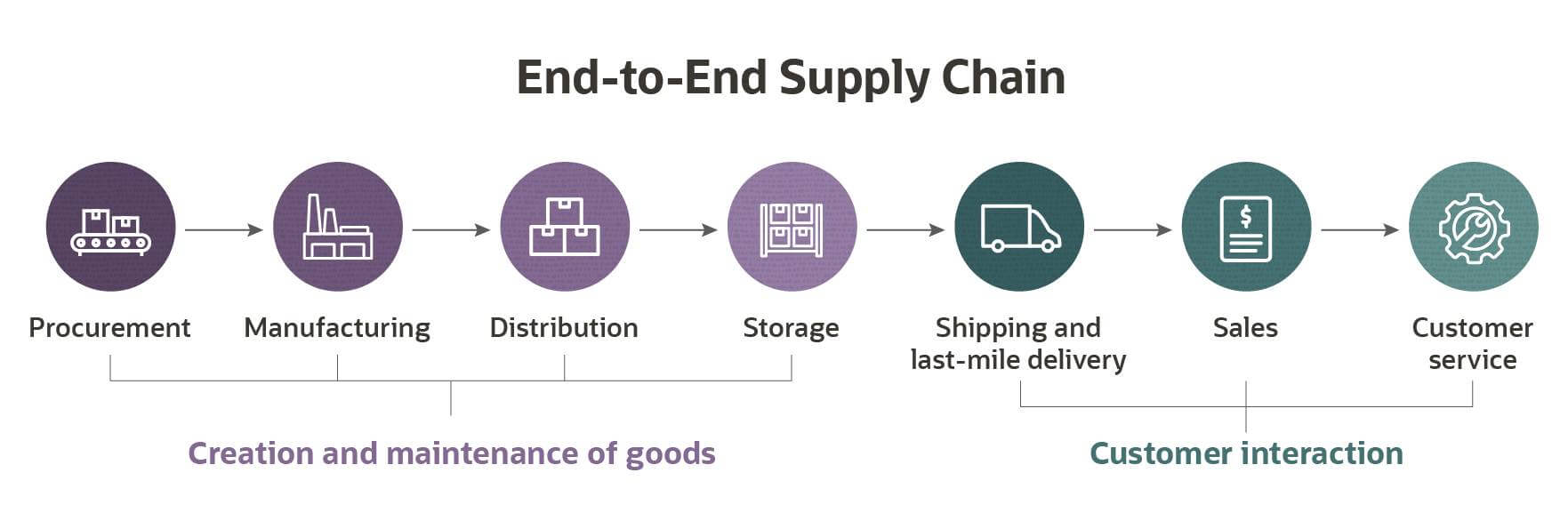

- E2E supply chains encompass every function in a business’s supply chain, including procurement, manufacturing, distribution, storage, shipping, delivery, sales and customer service.

- E2E supply chain management can be complex, but modern technology has made it more accessible and affordable for small and midsize businesses than in the past.

End-to-End Supply Chain Explained

An end-to-end supply encompasses the entirety of a business’s supply chain operations, including procurement, forecasting, demand planning, manufacturing, distribution, storage, shipping and delivery, sales and customer service, and provides visibility across all processes. This visibility is a necessity for businesses to effectively communicate, solve problems and provide service to partners and customers Any change made to one operation should be analysed from two perspectives: How does this impact the operation itself, and how, if at all, does it impact any other operations in the supply chain? The goal of E2E supply chain management is to optimise each function without negatively impacting the rest of the workflow.

For example, a siloed procurement operation may emphasize finding the lowest price for raw materials. An E2E supply chain, on the other hand, will weigh the benefits of paying a lower price against the time added to manufacturing if the lower-cost raw materials are inconsistent or of lower quality. Inferior raw materials may require more hands-on quality control to ensure that the components operate effectively, thereby increasing labour costs and the potential for wasted material in the manufacturing process. E2E supply chain analysts and managers must balance the pros and cons of reducing costs as much as possible without compromising quality or impacting later steps in the supply chain.

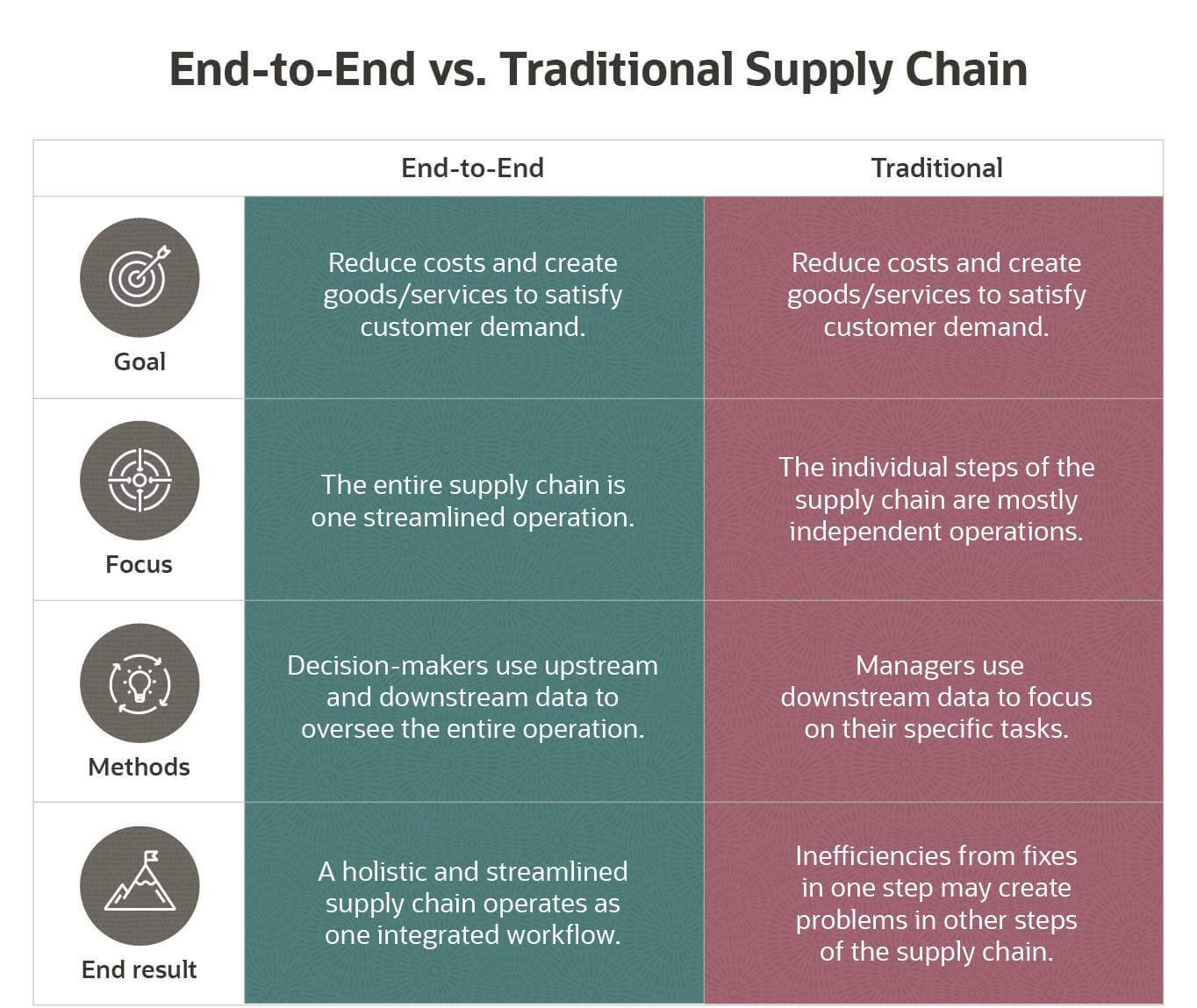

End-to-End vs. Traditional Supply Chain

End-to-end and traditional supply chains have the same overall goal of reducing costs and providing customers with goods or services. Both types of supply chains involve many of the same functions, such as manufacturing, shipping and customer service. However, a traditional supply chain primarily looks at each function of a business’s operation as an individual, stand-alone process with its own needs and goals, whereas an E2E supply chain views each function as a single step in a larger integrated process.

A traditional supply chain typically focuses on downstream information, with managers optimising output based on the inputs they receive from earlier steps in the supply chain. Basically, downstream visibility is focused primarily on how a business’s products are traveling down the chain to the customer. In an E2E supply chain, decision-makers also focus on upstream information, which provides visibility into how all the parts necessary to make those products are moving through the supply chain. Downstream and upstream information together create end-to-end supply chain visibility.

Here's a comparison for perspective: A manufacturing manager in a traditional supply chain operation may have little information on the procurement process aside from the inputs of raw materials they receive from their procurement colleagues. That same manufacturing manager in an end-to-end supply chain operation will have all the information they need from procurement, manufacturing and the functions that follow, such as customer delivery, to properly optimise manufacturing. To maintain that top-down perspective, E2E supply chain managers typically need access to large amounts of data and frequently turn to modern technology like cloud-based software to maintain an up-to-date and accurate look at the complexities of their business’s entire supply chain.

What’s Included in End-to-End Supply Chain Management?

End-to-end supply chain management includes every step of the supply chain, beginning with product design. Once a product is designed and ready to be created and sold, the seven major tasks of E2E supply chain management are procurement, manufacturing, distribution, storage, shipping and last mile delivery, sales and customer service.

Procurement

Procurement(opens in new tab) is more than just sourcing and ordering raw materials for the best price; it also includes estimating production lead times, checking stock levels to effectively allocate supplies and managing warehouse receiving. Without a well-managed procurement operation, factories won’t have the materials they need to produce goods. E2E supply chain management looks at all these aspects of procurement to ensure that the manufacturing team has everything they need — when and where they need it — to keep production moving efficiently.

Manufacturing

Manufacturing is the bread and butter of many businesses because without products to sell, no profit can be made. Delays at the manufacturing level can leave storefronts with costly stockouts and customers with frustrating back orders. For manufacturing to be properly optimised in an end-to-end supply chain, raw materials need to be sufficiently high quality to prevent waste and delays resulting from workers having to sort and remove inferior components. Once goods are finished, they must be organised and sorted for distribution. A warehouse may have perfected its assembly process, but if goods are not properly allocated, order fulfilment can suffer from shipping delays and lost products.

Distribution

At the distribution stage(opens in new tab) of the supply chain, products are finished and ready for sale. Many ecommerce(opens in new tab) businesses contract LSPs to fulfil their distribution, storage and shipping needs and improve their customers' experience(opens in new tab). For companies handling their own distribution, this critical step in supply chain management requires a close eye on inventory allocation. Inefficient distribution and shipping methods can lead to dissatisfied customers or empty shelves at retail locations, cutting into a business’s margins and hurting its bottom line. End-to-end supply chain managers can allocate inventory throughout a business’s reach to ensure quicker — and cheaper — delivery by keeping items closer to customers and shipping to retailers and distribution centres in bulk, rather than scrambling to fulfil individual shipments from a centralised location.

Storage

Businesses can manage their storage operations in several ways — by storing everything themselves, renting storage facilities or outsourcing to an LSP. Smaller businesses may be able to store everything themselves, but as they grow, contracting an external partner may become more affordable. However, businesses choose to store their materials and finished products, managing inventory is crucial to keep margins high. Too much stock leads to wasted storage costs — and potentially wasted goods if shelf life is short. Too little stock leads to back orders and lost profits as unsatisfied customers turn to competitors to meet their needs. End-to-end supply chain managers have visibility into the flow of goods, from manufacturing to their final destinations, to ensure that each step in the process has the resources it needs to efficiently meet customer demand.

Shipping and Last-Mile Delivery

Efficient inbound and outbound logistics(opens in new tab) can be the difference between a loss and a gain, especially for companies selling products with small profit margins. Customers expect fast shipping — often two days or less — and achieving that can present a challenge for companies with large networks of locations or customers. Some larger companies turn to LSPs or transportation management systems to handle the complexities of freight shipping, such as route optimisation and international customs, but smaller companies may find it more cost-effective to handle their shipping needs in-house. End-to-end supply chain managers should consider the costs and benefits of shipping options — and how they may impact other steps in the supply chain — to determine how to meet customers’ needs most effectively.

Sales

End-to-end supply chains, like most business functions, need to focus on the main event — selling a product. Sales teams need up-to-date data on what’s in stock and current prices, informed by production schedules, inventory records and current costs. Through E2E supply chain management, prices can be set and adjusted based on changes anywhere in the supply chain. For example, if procuring raw materials becomes more expensive because a supplier increased its rates, customer pricing can be quickly adjusted to prevent a delay that could lead to selling goods at a loss.

Customer Service

Some may consider the sale the final step in a supply chain — and for some businesses that may be the case — but many companies need to consider what happens next. Post-sales customer service is crucial to creating customer loyalty and enticing return customers. If a business offers warranties or maintenance, end-to-end supply chain managers must have comprehensive data on what services are offered and whether those services require their own material procurement or replacement items from a business’s inventory. Managers must also monitor reverse logistics (returns and exchanges), which can impact inventory levels and overall profits.

End-to-End Supply Chain Benefits

End-to-end supply chains provide businesses the same benefits as other types of supply chain management (opens in new tab), but it doesn’t stop there. Some additional benefits of E2E supply chain management are:

- More efficient operations: When looking for efficiency fixes, businesses that take a narrow view of the supply chain could cause one function’s fix to cause a headache further down the chain. For example, a faster sales process could lead to confusion for customers exploring returns, warranties or service options and end up complicating the customer service and reverse logistics process, tying up staff who could be focusing on other tasks. End-to-end management helps streamline and integrate the entire supply chain process so that improvements aren’t negated by unforeseen collateral damage down the line.

- Less risk of delays and supply chain breakdowns: A breakdown can occur at any point in the supply chain, from an unexpected supplier shutdown to a natural disaster closing delivery routes. E2E supply chain management provides visibility across operations so that decision-makers can see where vulnerabilities lie and plan for contingencies in the event of breakdowns, such as diversifying suppliers and shipping companies or changing how much on-hand inventory is distributed throughout a region.

- Increased customer satisfaction: The goal of supply chain management is to create a more reliable and affordable operation, both for the business and the customer. With E2E supply chain management, businesses can gain detailed tracking information and more accurate estimated arrival times based on up-to-date information from all parts of the production workflow — and share relevant information directly with customers. Even in the case of delays, quick customer notification and regularly updated timelines can be the difference between a patient but satisfied customer and an angry one who calls to cancel an order for a missing item.

- Better vendor relationships: E2E visibility into supply chain operations goes both downstream and upstream, benefiting the business and its suppliers. Managers using an E2E supply chain have a transparent and organised ordering process for their needed supplies and services, and vendors can avoid the scramble of forced rush orders or frantic emergency shipments by having a more thorough understanding of what their clients need — and exactly when and where they need it. An additional perk: Happy vendors are more likely to offer clients better credit terms or discounts.

- Transparency in operations and inventory: Businesses with visibility across their supply chain can see a detailed view of every step of production — complete with inventory/supply levels and production schedules — to prevent or address bottlenecks, over/under stocks and manufacturing delays. Because of the amount of data needed for a comprehensive view of an end-to-end supply chain, many businesses, especially ecommerce companies(opens in new tab), use software and a unified business platform to keep the data organised and accessible to managers at every level of the supply chain.

- Better data for analysis, forecasts and improvements: All the data collected during the E2E supply chain process can be used to better forecast customer demand, production schedules and more. Instead of flying blind and hoping to produce enough for a potentially busy season — without producing too much — accurate demand forecasts can keep shelves stocked just enough and minimise carrying costs and waste. Accurate data also allows supply chain managers to identify flawed or outdated links in the supply chain so they can be addressed before major issues arise. After all, managers can’t fix what they can’t see.

End-to-End Supply Chain Challenges

E2E supply chain management can present challenges, especially for small businesses, because of the size and scope of the data and visibility needed to fully understand every aspect of the supply chain. Challenges facing end-to-end supply chain managers include:

- Complexity: The intricacies of the supply chain can make visibility into every function and operation difficult to achieve. Measurements, such as inventory levels, available supplies and shipment tracking, can lag and communication breakdowns can occur. For many small businesses implementing end-to-end supply chain management for the first time, coming up to speed and gaining the necessary visibility may require an investment in a more sophisticated business platform than they currently use, which can be costly.

- Delays in cost-cutting improvements: End-to-end supply chain managers need to focus on the big picture and the interconnected elements of the supply chain. But that can sometimes cause delays in cost-saving measures as decision-makers miss the trees for the forest. For example, if a supplier is offering new customers a lower price than a business’s current vendor on comparable-quality materials, managers may spend too much time weighing the impact on the supply chain and miss out on the opportunity. Sometimes quicker thinking can create benefits that deep analysis can miss, so managers need to find the right balance.

- Overpromising and underdelivering: To gain customers’ trust, businesses may unintentionally give too much visibility to customers and create unrealistic expectations. For example, if a business is overconfident in its delivery tracking system and processing times, it may promise estimated delivery times or give automatic tracking information to customers for “shipped” items that are still being processed. If a shipping label is printed and the information is forwarded to customers days before the goods end up on a truck, it may frustrate customers more than if the order was listed as “shipped” a few days later. Businesses excited to implement these end-to-end functionalities shouldn’t get ahead of their skis; unexpected delays or lagging order fulfilment can cause more customer-service problems than benefits. Over time, familiarity with end-to-end analysis should close the gap between new features and how best to use them.

Best Practices for Optimising End-to-End Supply Chain

Visibility into the end-to-end supply chain is the cornerstone of E2E management, and that visibility is critical to inform what comes next — improving a business’s operations. Here are some best practices to help businesses capitalise on their increased supply chain visibility.

- Share information throughout the supply chain. It’s important for every middle manager or team leader throughout the supply chain to have access to current data and strategies. By creating a well-connected network that includes suppliers, the workforce and customers, businesses can create stronger relationships than their competition, leading to higher quality and loyalty from every party.

- Emphasize demand planning to keep inventory just lean enough. Demand planning is one of the most important ways to control the supply chain and inventory levels. Overstock clutters warehouses and storage facilities, raising carrying costs and slowing order fulfilment. Understock pushes customers to competitors while they wait for back-ordered items. Companies using demand planning, often through automated data collection and market research, can stock just enough to meet demand and keep customers, as well as bookkeepers, happy.

- Prioritise a reliable workforce. End-to-end supply chains are only as effective as the staff handling each step. Managers with an adaptable and knowledgeable staff can quickly implement changes and avoid breakdowns in the supply chain by tapping into the expertise of their workers. Companies with high employee retention and effective training programs are better suited to the complexities of the E2E supply chain than companies that rely on new hires because of heavy turnover.

- Automate or outsource weaknesses. When weaknesses are identified, decision-makers can either fix them in-house or outsource solutions. For in-house fixes, many companies turn to modern technology, such as automation, to handle certain tasks more efficiently than their current manual workflow — for example, automating inventory tracking for order updates, payment status and delivery confirmations to free up staff to work on higher-value tasks. Companies that lack the expertise to efficiently run a particular supply chain function in-house may outsource part or all of that function to a third party. For instance, a business unable to meet its shipping needs may contract a third-party LSP for a more cost-effective solution rather than invest in a new fleet of delivery vehicles and warehouses.

- Set benchmarks. Supply chain managers need ways to measure the success or failure of proposed optimisations over time. Benchmarks can help set goals, and regular check-ins on progress can help managers decide what works and what doesn’t, so they can plan the next set of improvements.

Your Supply Chain Analytics Decoded

End-to-End Is the Future of Supply Chain. NetSuite Can Get You There

Every business needs to manage its supply chain, but not every business has the capabilities to collect and analyse the data required for effective end-to-end supply chain management. NetSuite Supply Chain Management gives businesses visibility into every step of their operations so they can continuously identify areas for improvement and understand how those improvements will impact the rest of the workflow. NetSuite’s cloud-based platform uses data to help managers monitor steps, from procurement and production to delivery, to ensure up-to-date and accurate information throughout the supply chain for the business and its suppliers and customers.

For ecommerce companies with complex and far-reaching E2E supply chains, NetSuite Ecommerce helps connect businesses with customers by driving web traffic to a mobile-optimised order management system. NetSuite Ecommerce — paired with ERP — gives supply chain managers real-time visibility into inventory management, customer service, financials and more. With NetSuite, businesses can handle their E2E supply chain needs all from one unified platform.

The supply chain is the artery through which a business’s lifeblood — its products — must flow, from the first design blueprint to the final sale to the customer. But businesses facing unexpected breakdowns in their supply chains are often left scrambling to find new suppliers, distributors or delivery services. Thanks to advanced technologies, such as cloud-based software and blockchain, companies can collect and analyse data to effectively manage end-to-end supply chains, which look at the supply chain as one holistic operation instead of as separate siloed processes.

By managing the supply chain as a single streamlined workflow, businesses can optimise the entirety of their operations instead of one task at a time, preventing redundancies and the domino effect of a decision in one step of the supply chain creating problems down the line. E2E supply chain management can help businesses create highly efficient and reliable operations that have the flexibility to weather supply chain breakdowns while reducing costs and increasing customer satisfaction.

#1 Cloud ERP

Software

End-to-End Supply Chain FAQs

Where does the supply chain end?

The supply chain ends with post-sale customer service, such as warranties, returns and ongoing maintenance. However, some businesses may not offer these services, so their supply chain ends with the sale.

What is preventing end-to-end supply chain visibility?

End-to-end supply chain visibility can be difficult to achieve because of the scope of data required to get a full picture of every step in the supply chain. Many companies turn to automated systems and unified business platforms to give managers the visibility they need to effectively manage the supply chain.

What is end-to-end distribution?

At the distribution stage of the supply chain, products are finished and ready for sale. End-to-end supply chain managers can allocate inventory throughout a business’s reach to ensure quicker — and cheaper — delivery by keeping items closer to customers and shipping to retailers and distribution centres in bulk rather than scrambling to prepare individual shipments from a centralised location.

What are the three stages of the supply chain?

Some analysts segment the supply chain into three stages:

- Procurement of raw materials through sourcing and purchasing.

- Planning, scheduling and manufacturing goods.

- Logistics, including storage, distribution and delivery of goods.

What are the four stages of the supply chain?

In addition to the first two primary stages — procurement and manufacturing — some analysts split logistics into internal logistics (storage and distribution) and the final last-mile delivery to the customer, creating four stages of the supply chain — procurement, manufacturing, internal logistics and delivery.

What are the five stages of the supply chain?

- When the supply chain is broken into five stages, the important steps are:

- Strategic planning, including a company’s infrastructure and the components needed to execute the business’s workflow.

- Sourcing supplies and raw materials needed to keep the business operating.

- Executing the primary business function — producing goods for sale to customers.

- Delivering goods or services to customers.

- Reverse logistics through returns and customer service.